Many embark on a renovation project during the start of the year. After all, it is the perfect time to change things up whether at home or office to give a sense of fresh start or new beginnings.

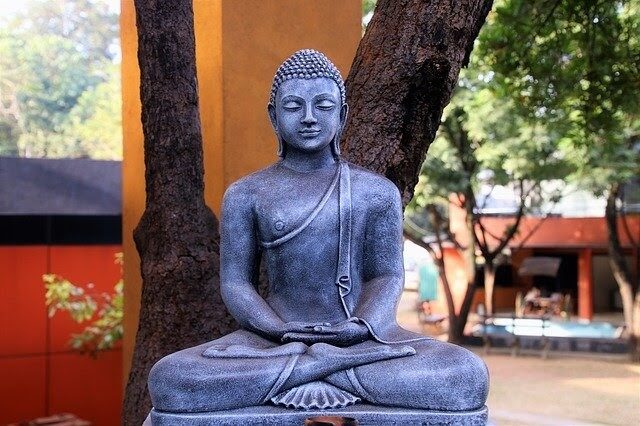

1) Nature-inspired home decor

This year, interior designers see that there will be a continued focus on regaining our connection to the natural world through the use of nature-inspired home decor. This might also mean that there will be an emphasis on creating calming environments with natural lighting and ventilation, plants, and other visual connections with nature.

To achieve this in style in your home or even office space, think of something that helps you connect with nature. It may be succulents, printed carpet, or sculptures like shown above.

2) Sustainable materials for home design

Because of climate change and other environmental problems, sustainability and the use of organic and dependable materials have become increasingly significant in recent years. As a result, many artists are expected to place a greater emphasis on the ethical manufacture and use of home materials. Extending the life of household products will be critical to ensuring that less resources are required in the long run and that there will be no additional waste.

At LIQMET, we’re contributing to this very important shift in the industry by making only the best and durable liquid metals with a 30-years warranty. Another objective we set for ourselves ever since when we started was to stay away from hazardous materials. We spent six months developing and testing several polymers. As a result, we no longer use polyester resin in our production. Our decorative metal coatings are odourless and require no extra safety equipment to apply.

3) Personalisation

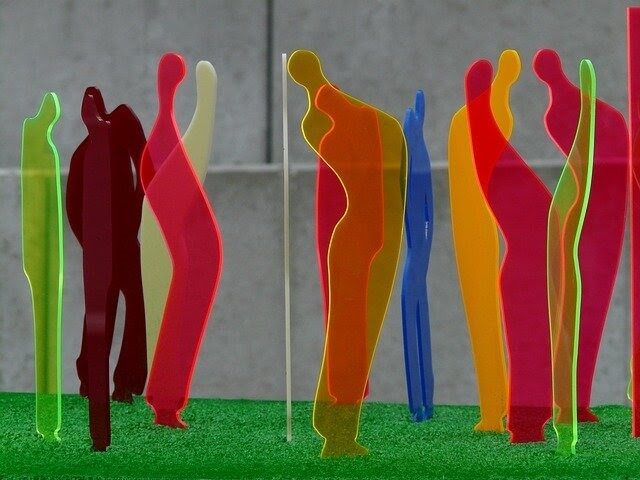

Interior design experts also see 2022 as a year that will bring a greater awareness of our surroundings and their impact on our emotions and well-being. There will be a focus on individuality and personal ties to the occupant’s interests, likes and hobbies. DIY home decors will take the centrepiece, and the primary consideration when choosing a decorative piece will be “will it reflect your personality and will it make you feel better?”

Add splash of personality and colour to your home

Are you thinking of a DIY project to kickstart your home refresh in 2022? Order LIQMET liquid metals today! LIQMET liquid metals can be applied to any surface including sculptures, bathroom sinks and tubs, vehicles, interiors, kitchens, fireplaces and more.

We deliver worldwide (except Bahrain). We can also connect you to our registered applicators so you need not worry about liquid metal application.

It’s a known fact that liquid metals are beautiful with their lustrous look that feels just like real solid metals. They’re also known to be useful for decorative pieces, interior design, and art. But did you know that more than its aesthetics, liquid metals have a lot more benefits? Let’s go through them one by one.

Lightweight

Compared to sheet or forged metal, liquid metals are lighter in terms of weight. Meaning, it is easier to position and apply. But this doesn’t mean that liquid metals aren’t sturdy. In fact, because they’re lightweight, it was easier to erect when applied to an MDF board.

Cost-effective

Along with its weight, liquid metals are preferred by many because it is much more cost-effective than regular metals. When applied on an MDF board, you need not buy any extra strengthening for support.

If you’re wondering how much liquid metal costs, the flat-rate for any LIQMET sample pot is $30.00 plus the delivery fee to your location or country. 0.55 kg sample kits pots are the best way to experience LIQMET colours before taking the plunge. They are available in every current LIQMET colour and are available for worldwide delivery.

Eco-friendly

Liquid metals, specifically LIQMET liquid metals are mostly made from recycled materials to give you peace of mind that they are not harmful to the environment. Another objective we set for ourselves when creating liquid metals was to stay away from hazardous items. We spent six months developing and testing several polymers. As a result, we no longer use polyester resin in our production. Our decorative metal coatings are odourless.

Can be fire-retardant

Aside from environmental safety, we also place importance in personal safety. This is why we have a fire-retardant range of liquid metals. Meaning, the substances in these liquid metals are able to help slow down, stop, or diminish the intensity of a fire.

Beneficial for almost all industries

Currently, LIQMET liquid metals are used in almost every industry involved in construction, interior design, and the arts. To give you a clearer picture, LIQMET liquid metals are used for the following:

This list is not exhaustive, meaning, your creativity is the limit! LIQMET liquid metals can be used for practically everything that involves decoration and coating.

Explore LIQMET liquid metals

What are you waiting for? Order LIQMET liquid metals today! We deliver worldwide (except Bahrain). We can also connect you to our registered applicators so you need not worry about liquid metal application.

The holidays are just around the corner, and with it, the most wonderful time of the year. Holiday tunes are everywhere, reds and greens are in, the spirit of giving and gratitude is in the air, and for everyone who loves decorating, it’s the best time to decorate your home or office!

At LIQMET liquid metals, we love this season and we love to help you achieve the best holiday decor yet! So we thought it best to compile some holiday decor inspirations for you using liquid metals. But why liquid metals, you may ask? Well, they have a natural sheen and are available in holiday-themed colours. Plus, they are very durable. Meaning, you can use your holiday decor this year and the next!

Shining, shimmering Holiday signs

First impressions last. And what better way to leave a great first impression to your guests than to have a festive, sophisticated golden Holiday-themed sign hanging to your door? You can customise your sign to include any message or element you want. Then coat it with liquid metals in festive colours such as gold, tahiti, and copper.

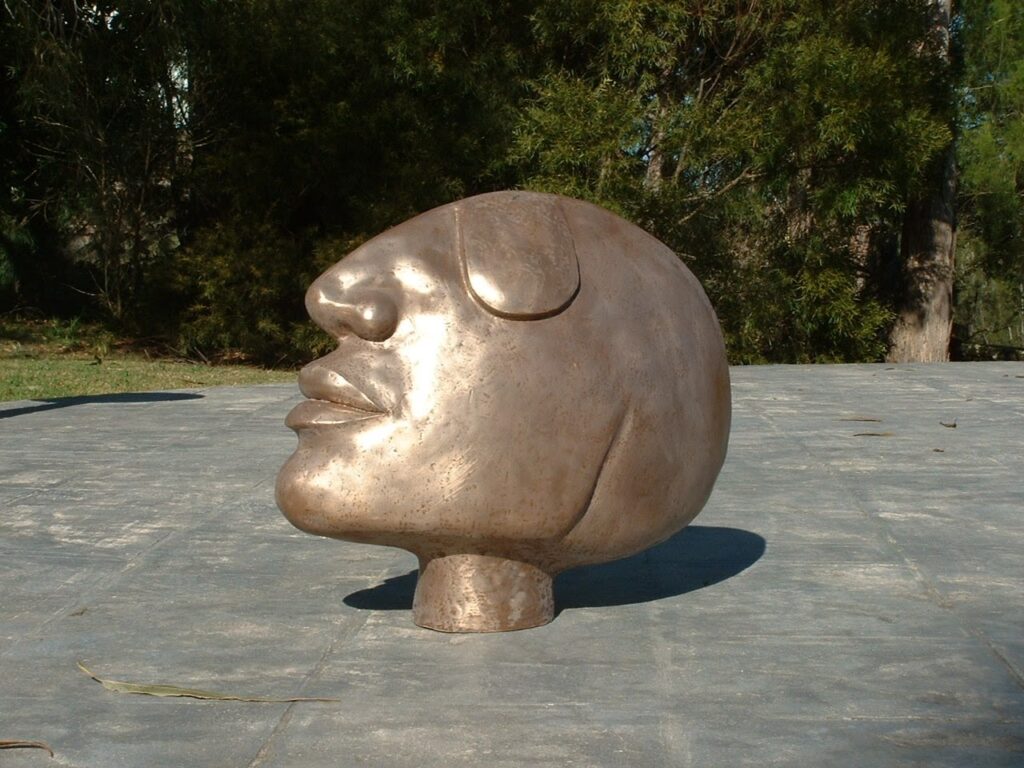

Holiday-themed sculptures

Accessorise your living room by adding holiday-themed sculptures coated with liquid metals! Metal coatings from LIQMET can substantially improve the appearance of sculptures by adding that lustre. LIQMET’s cast look and tactile sense of the surface allows for more cost-effective and higher-quality manufacture. Similarly, LIQMET can be used on decorations made from concrete, ceramics, and other common materials in the industry.

Jingle balls

What is holiday decor without Christmas balls, right? Enhance the look of your typical ornaments by adding decorative liquid metal coatings. Don’t worry, while they look and feel like real metals, they’re lightweight and won’t weigh your foundations down.

Don’t risk any delay, order liquid metals for your holiday decoration

What are you waiting for? Order LIQMET liquid metals today! We deliver worldwide (except Bahrain). We can also connect you to our registered applicators so you need not worry about liquid metal applications.

Think you’re missing out when you use liquid metals instead of solid, raw metals? Think again. Liquid metals are real metals and they also have the lustre and durability that metal sheets have to offer. Most of the time, liquid metals are even better because you can create different textures without losing that head-turning shine.

Liquid metals are more cost-effective than using solid metalsJust because they’re on par with solid metals doesn’t mean they have to be as costly. Liquid metals are generally more affordable because the production of solid metal sheets alone is costly. Plus, you also need to shell out money on cutting, installing and bracing solid metals.On the other hand, liquid metals are lightweight materials that can be easily applied to a variety of surfaces (more on this later). A sample pot of highly versatile liquid metals costs only around 30 AUD.Liquid metals can be applied to a variety of substratesWe’ve already mentioned earlier that liquid metals can be applied to almost any surface. But just in case you’re still wondering, here’s a list of substrates where you can apply liquid metals: